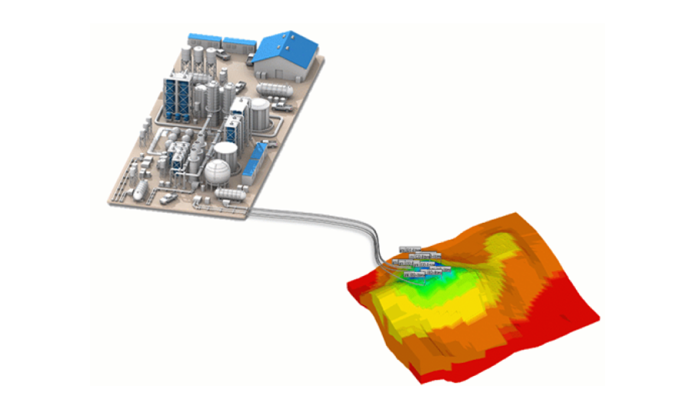

Integrated Production System Modelling

CoFlow™ is the industry’s first enterprise solution that allows reservoir and production engineers to truly collaborate on the same asset.

The multi-fidelity, multi-disciplinary, and multi-reservoir capabilities result in superior engineering and economic decisions, time savings when going from concept to field implementation, and optimization of field operations for high stakes assets.

Unified Integrated Production System Modelling (IPSM)

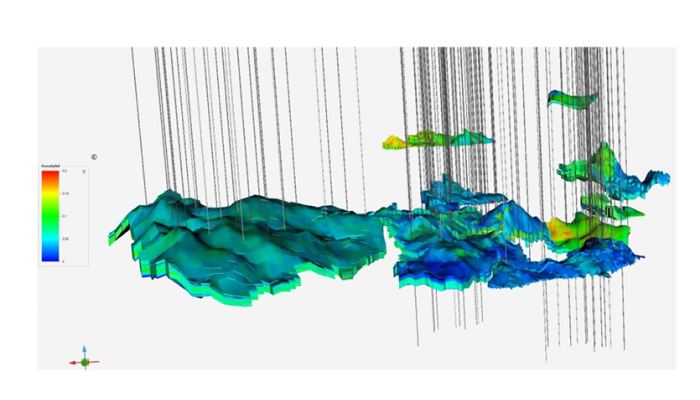

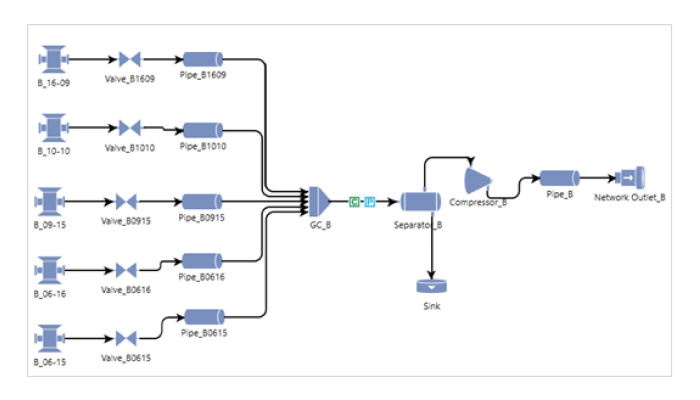

CoFlow is the only IPSM solution that ensures data consistency across disciplines and at interfaces of IPSM model components (reservoir – well – facility). The proprietary fluid blending techniques allow the use of different fluid models in reservoirs, wells, and facilities and blended fluid models at all fluid mixing locations, to enable accurate fluid behavior from sandface to process equipment, for all hydrocarbon and CO2 sequestration applications.

Seamless Workflow for Investment Decisions

Coupled with CMOSTTM, CoFlow enables a truly integrated uncertainty and optimization workflow where big investment decisions can be gauged with attention to subsurface uncertainties, allowing anything from reservoir to production facilities to be parameterized.

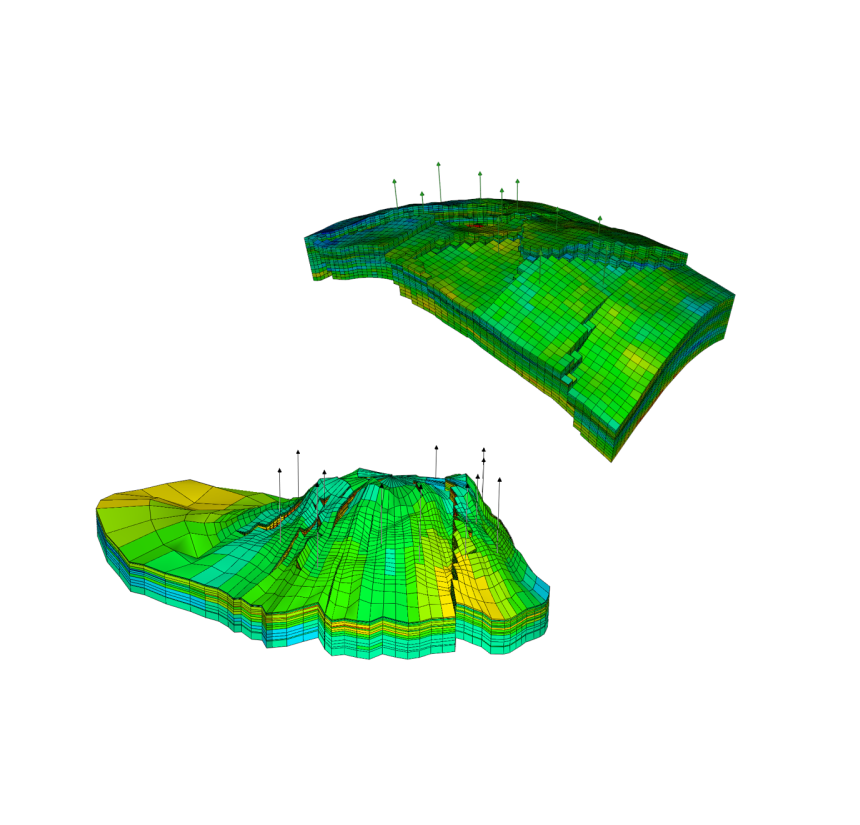

Optimize IPSM Models for Cost-Effective Accuracy

Increase accuracy without sacrificing cost by choosing the fidelity of various IPSM model components based on objectives and available data. Build fit-for-purpose models with cross-discipline sharing with high performance and no loss of accuracy. Combine production and reservoir models to create a single integrated model of your complete asset.

Streamlined and Easy-to-Use

Traditional IPSM workflows require expert users to set up the integrated production simulation model. Using the modern IPSM workflow, CoFlow is designed to improve usability and productivity across all disciplines, as well as user experience.

The single platform allows teams to easily audit and quality control models. An easy-to-use interface includes a comprehensive set of integrated workflows which enables all skill levels to successfully create and set-up IPSM projects. The extensible architecture allows organizations to add proprietary technology or seamlessly interact with other tools in their corporate workflow. The full Application Programming Interface (API) allows users to customize the workflow for reservoir or production engineering best practices.

Benefits

- Easy coupling of reservoir models to production systems and advanced network solver to handle asset planning, contracts, deliverability, and development options.

- Versatile wellbore design capabilities enable completions engineered to the evolving nature of reservoir performance.

- Database structure to ensure asset teams work from the most up to date iteration of the model.

- Single vendor integrated IPSM platform that’s faster and more stable than connecting third-party solutions.

- Multi-disciplinary collaborative environment for reservoir and production engineers.

Key Features

- The only industry solution that allows for robust design of well completions and surface facilities with consideration for subsurface uncertainties.

- Model multi-reservoir with varying degrees of fluid complexity and blending.

- Extensible plug-in framework supports proprietary technology deployment.

- The system is optimized for both performance and accuracy through the use of advanced coupling techniques and network solvers.

- Further advancements to fluid modelling capabilities including handling of pure CO2 phase behavior.

Related Resources

Take your technical skills from the classroom to your workplace

CoFlow™ is the industry’s first enterprise solution that allows reservoir and production engineers to truly collaborate on the same asset.