Intermittent cyclic steam injection reversed production decline in a mature Colombian field. Using CMG STARS, the production trend shifted from a 23% annual decline to a 25% annual growth rate, resulting in a reduction of 20,000 MMBTU of steam and reduced service work, with no new infrastructure or additives required.

Field Background

Heavy oil fields developed through Cyclic Steam Stimulation often face diminishing returns after repeated cycles. In Colombia, a mature heavy oil field had been under CSS since 2002. With viscosities ranging from 8,000 to 10,000 cP, the field was originally developed using vertical wells and steam injection cycles repeated over many years. More than 15 cycles had been applied in each well, and over time, production declined. Reservoir pressure dropped below 150 psi. Water production increased. The steam was no longer reaching the right zones. Traditional CSS no longer had an effect.

The Challenge

The production decline made it clear that a new approach was needed. The team faced steep limitations. There was no room for new additives or major infrastructure upgrades. The water cut was rising. Recovery was falling. The traditional approach had run its course.

The question was simple. Could a new strategy be found using what was already in place? One that required no additional materials, no changes to surface facilities, and no large changes to the schedule?

Rethinking the Approach

To answer that question, the team turned to simulation. Using CMG's STARS, they modeled different injection scenarios. The goal was to test what could be done without relying on external additives or equipment.

The simulations tested five strategies:

- One well per month (conventional CSS)

- Four wells per month (group CSS)

- All wells at once (simultaneous CSS)

- Sequential rotation across wells

- Intermittent injection into two central wells

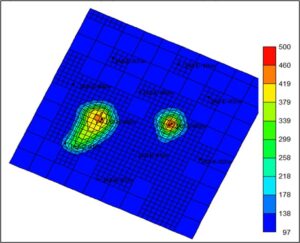

Each had different patterns of heat contact, recovery, and steam use. Intermittent CSS showed the widest contact area and the largest effect on under-swept regions.

The team noticed that repeated cycles were only affecting the area immediately around each well. Reservoir pressure was already too low to drive production. Water saturation was high. The injected steam was not reaching the zones that still held oil. This meant more steam was going to the same spent zones, leading to diminishing returns.

Field Execution

The team used what the model showed. Rather than inject across all twelve wells, they targeted two wells at a time. These wells received steam for 216 days while the others continued on production. After the cycle, they switched the wells. The longer cycles allowed more steam penetration, reaching zones that had never been touched by prior cycles. Steam was focused instead of spread thin.

The work required no new surface lines. The injection schedule followed a rotation. The approach reduced well service calls. Only two wells at a time required attention. The rest stayed online.

Simulation as a Planning Tool

Before the pilot, simulation gave the team the clarity they needed to take the plan into the field. CMG’s STARS showed that intermittent injection would reach deeper and wider into the reservoir. It showed where water saturation would drop and oil mobility would rise. It also showed that the approach would require less steam, not more.

The intermittent method was forecast to recover 630 MBBL, compared to 572 MBBL from sequential injection. The oil-steam ratio rose to 1.31 BBL per MMBTU. The best injection rate was set at 300 BEWPD, or about 110 MMBTU per day.

With these results, the team had what they needed to move forward. The model did not just guide planning. It shaped it.

Pilot Results

The pilot ran for one year. The impact was clear:

- The production shifted from a 23% annual decline to a 25% annual growth rate

- Steam use dropped by 20,000 MMBTU

- 7,850 barrels of oil were added

- Water production declined

- Well service calls dropped from 51 to 27

This was done using existing equipment. No additives. No surface rework. The field delivered more with less steam and fewer interruptions.

Practical Gains from a Simple Shift

A continuous steamflood was considered but ruled out. It would have required major work and investment. Steam capacity and surface lines could not support it. The intermittent method offered a simpler path. The team made better use of what they already had. They focused effort, extended cycle duration, and drew production from new zones without touching the surface layout.

Rewriting the Approach

The team used STARS to challenge a long-standing routine. They tested an approach that did not rely on expansion or additives. They redirected the field's steam strategy. By moving to intermittent cycles, they extended the sweep, reduced waste, and brought production back up.

This case shows how simulation can break through assumptions. The tools made it possible to test options that were not obvious. The field delivered more oil, used less steam, and required less intervention.

The answer was to think differently about how to apply what was already there. CMG's tools helped make that possible.

This case study is a part of CMG’s Subsurface Stories, where we share real stories, real data, and real results.