Fast Track your CCS Roadmap.

From storage sites selection to injecting CO₂ in complex geologies, CMG equips you with the most advanced and trusted CCS ecosystem, backed by experts who’ve been delivering CCS projects worldwide since 1998.

One Solution.

All Phases.

Total Certainty.

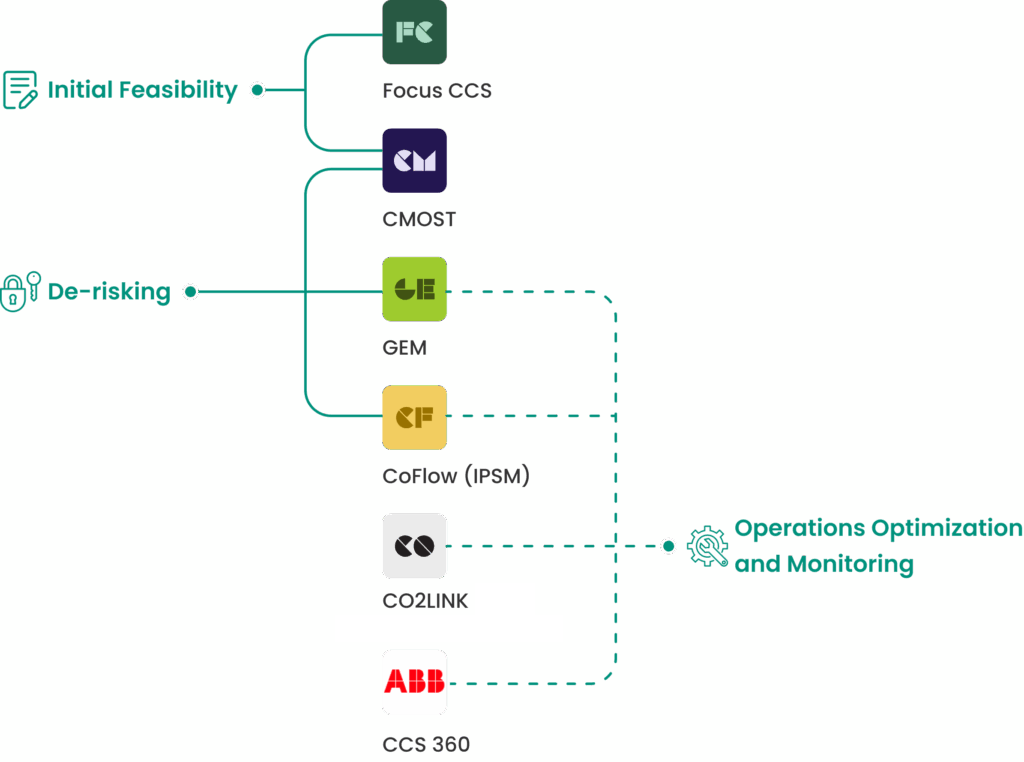

CMG brings unmatched integration across the entire CCS lifecycle from scoping to injection, monitoring, and optimization. Seamlessly move from early planning to full-physics simulations and operational decision-making with one trusted solution suite.

Initial Feasibility

Initial Feasibility

- Geological site selection

- Validate asset viability quickly

- Access more storage capacity

De-risking

De-risking

- CO₂ trapping mechanism

- CO₂ plume monitor and surveillance

- CO₂ injectivity evaluation

- CO₂ chemical interaction with reservoir fluids

- Probabilistic storage capacity

- Reservoir and cap rock stress evaluation

- Evaluation of potential interference with legacy wells

Operations Optimization and Monitoring

Operations Optimization and Monitoring

- Sub-surface to surface modelling

- Well integrity assessment and flow assurance

- Regulatory reporting

- System corrosion monitoring

- MMV (Measurement, Monitoring and Verification)

Support, Training and Consulting Services during the lifecycle of your CCS projects

CMG’s CCS

Solution Offers

- Focus CCS

Rapid feasibility and storage validation in minutes, even for non-specialists.

- CMOST

Automated sensitivity and uncertainty analysis supporting optimal project design and rapid permitting.

- CO2LINK

Dynamic link between CCS simulator (CMG GEM) and the Transient wellbore simulator (KDI LedaFlow) for the modelling of complex CO2 phase transition systems.

- GEM

Accurately simulate complex physics and chemistry of CO₂ injection into the subsurface to determine near and long-term viability, ultimately reducing the risks to your CCS project.

- CoFlow

Asset-wide CO2 transport and multi-site injection optimization with pipeline, surface network, and wellbore modeling, scalable for multi-cluster hubs.

- CCS 360

Full operational view of the CCS network from capture to storage with real-time alerts for fault activation, temperature and pressure changes, corrosion conditions, reducing unplanned maintenance and downtime.

You need a partner who’s done this before.

CMG’s subsurface simulation tools are trusted by every supermajor and used in the most complex CO₂ injection projects worldwide, from feasibility through final containment.

From Storage to Certainty.

Keeping it Reliable and Efficient

To keep your CO₂ storage network running reliably and cost-effectively, ABB, and CMG deliver an integrated platform that minimizes downtime and maximizes performance. With real-time monitoring, you can detect faults, temperature shifts, and pressure anomalies instantly, enabling swift, proactive intervention before they escalate into costly disruptions.

You can manage CO₂ injectivity levels across the network in real time to optimize energy use, reduce operational overhead, and ensure uninterrupted injection with efficient and long-term CO₂ containment.

Storing CO₂ isn’t new to us. We make carbon storage simple, scalable, and regulator-ready.

- 40+ years of reservoir simulation expertise

- More than 350+ citations and counting

- Fully integrated modeling, from injection to plume containment