Compositional, Unconventional & Advanced Processes Simulator

GEM™ is the leading reservoir simulation software for compositional, chemical, and unconventional Equation of State (EoS) based reservoir modelling.

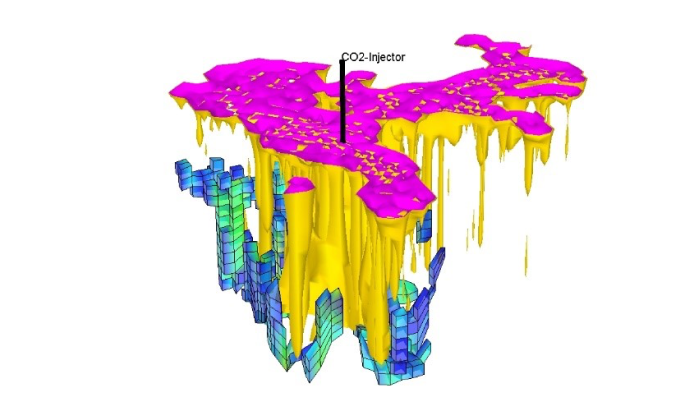

Accurately replicates the subsurface fluid flow and interactions to assist in field optimization and to maximize hydrocarbon recovery. GEM is widely used to capture unconventional shale liquids production and is the gold-standard simulator for CO2 and H2 storage processes.

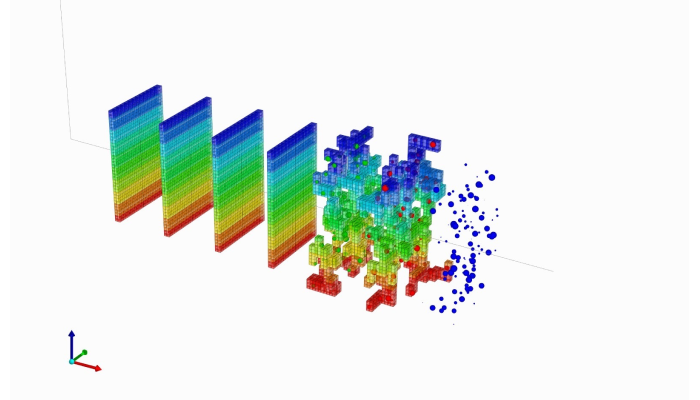

Simulation for Unconventional Reservoirs

Simulate natural and hydraulic fractures, multi-component adsorption and desorption, geomechanical effects, inter-phase mass transfer, multi-phase diffusion and non-Darcy flow for unconventional shale as well as coal bed methane production.

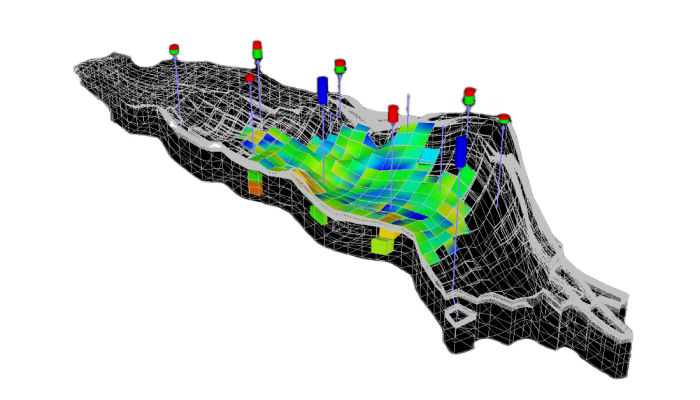

Improve and Optimize Recovery Factors

Understand the impacts of key phenomena including miscible/immiscible displacement, chemical EOR, and non-steam based thermal recovery processes when improving and optimizing the recovery factor of an oil and gas asset.

Advanced Evaluation and Design

Design and evaluate the effectiveness of chemical additives with advanced cEOR features such as polymer, surfactant, foam, and ASP type enhancements.

Optimize Recovery and Reduce Environmental Impact

Maximize oil recovery and reduce environmental impact with accurate simulation of Low Salinity Waterflood (LSW) mechanisms, including geochemistry and wettability alterations, accounting for ion exchange, and zeta potential influences on the process.

CO2 Injection for Subsurface Viability Assessment

Simulate the long-term effects of carbon dioxide (CO2) injection into the subsurface environment, in particular saline aquifer or depleted hydrocarbon reservoirs, thereby helping determine the viability and reducing the risk of any CCS project

Benefits

- Capture how fluid properties and the system phase behaviour changes with pressure, temperature, and composition.

- Accurately model naturally and hydraulically fractured reservoirs.

- Utilize full physics for modelling foam and other cEOR processes.

- Capture effects of geochemistry and clay distribution when modelling LSW.

- Model geomechanical effect of stress and strain to understand effects on production.

Key Features

- Full field Equation of State (EoS) based adaptive-implicit compositional reservoir simulator.

- Massively parallel capability.

- Dynamic Gridding Refinement and Coarsening.

- Chemical EOR modelling capabilities for polymer, surfactant, ASP, foam.

- Full thermal capability including Joule Thompson effects.

- One and two-way coupled finite element geomechanics including thermal geomechanical effects.

- Flexible and extensive geochemical capability coupled with equilibrium and rate dependent reactions.

- Oil-water-gas flash with water being an active fluid allowing for any water based interactions.

- Advanced capability Tracer module for tracking individual molecules in the simulator.

- DUALPOR and DUALPERM capability, additionally coupled to explicit discrete fracture network (DFN) and hydraulic fracturing capabilities.

- Grid independent wells.

Related Resources

Take your technical skills from the classroom to your workplace

GEM™ is the leading reservoir simulation software for compositional, chemical, and unconventional Equation of State (EoS) based reservoir modelling.