Black Oil & Unconventional Simulator

IMEX™ is the leading black oil reservoir simulator for modelling primary, secondary, and tertiary oil recovery processes.

Quickly screen prospects, set up pilot designs, monitor and optimize field operations, and improve production performance.

Reservoir Modelling for Reliable Forecasts with AI

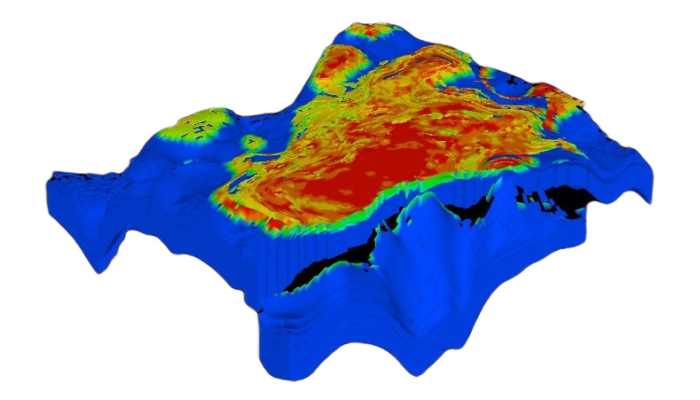

Model simple to structurally complex, heterogeneous, faulted, and fractured oil and gas reservoirs, using small to very large scale multi-million grid cell models to achieve reliable production forecasts. Use an Adaptive-Implicit formulation along with integrated artificial intelligence to minimize run times without sacrificing data integrity.

Accurate Production Forecasting

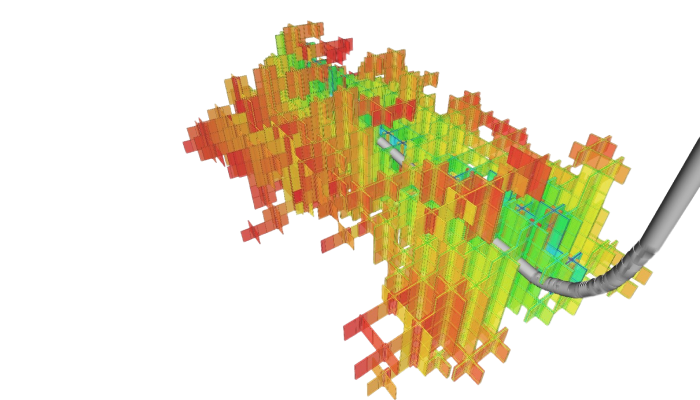

Model naturally and/or hydraulically fractured reservoirs to accurately capture transient flow behaviour and to achieve more accurate and better production forecasts.

Intelligent Wellbore Flow and Pressure Modeling

Model the flow and pressure change throughout the wellbore branches, tubing strings, and equipment with an intelligent segmented wells module.

Field Development Optimization for Complex Reservoirs

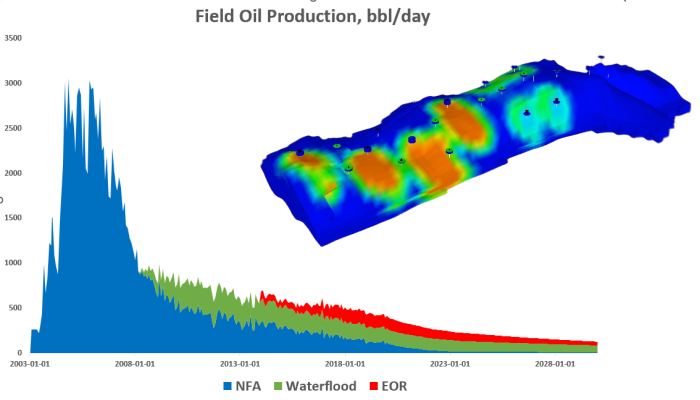

Evaluate and optimize field development plans and predict recovery for primary and secondary recovery methods in complex and heterogeneous reservoirs. IMEX allows for fast analysis of complex recovery mechanisms using a simplified black oil approach before moving to GEM™ or STARS™ for more detailed analysis. These processes include, but are not limited to, Low Salinity Waterflood; Polymer; Surfactant; Miscible gas injection.

Benefits

- Quickly screen various recovery mechanisms before moving to more complex simulations.

- Model complex hydraulic fracture networks, and all associated effects, to accurately history match field results.

- Fast and easy transition to EOR process modelling in GEM™ and STARS™.

- Seamless integration with CMOST™ for rapid history matching and optimization of reservoir management workflows.

Key Features

- Full field black oil adaptive-implicit reservoir simulator.

- Massively parallel capability.

- Chemical EOR modelling capabilities for polymer.

- Pseudo-miscible gas flooding.

- Impact of thermal effects on behaviour of injected or reservoir fluids.

- One and two-way coupled finite element geomechanics including thermal geomechanical effects.

- Advanced capability Tracer module for tracking individual molecules in the simulator

- DUALPOR and DUALPERM capability, additionally coupled to explicit discrete fracture network (DFN) and hydraulic fracturing capabilities.

- Grid independent wells and detailed segmented well model.

Related Resources

Take your technical skills from the classroom to your workplace

IMEX™ is the leading black oil reservoir simulator for modelling primary, secondary, and tertiary oil recovery processes.